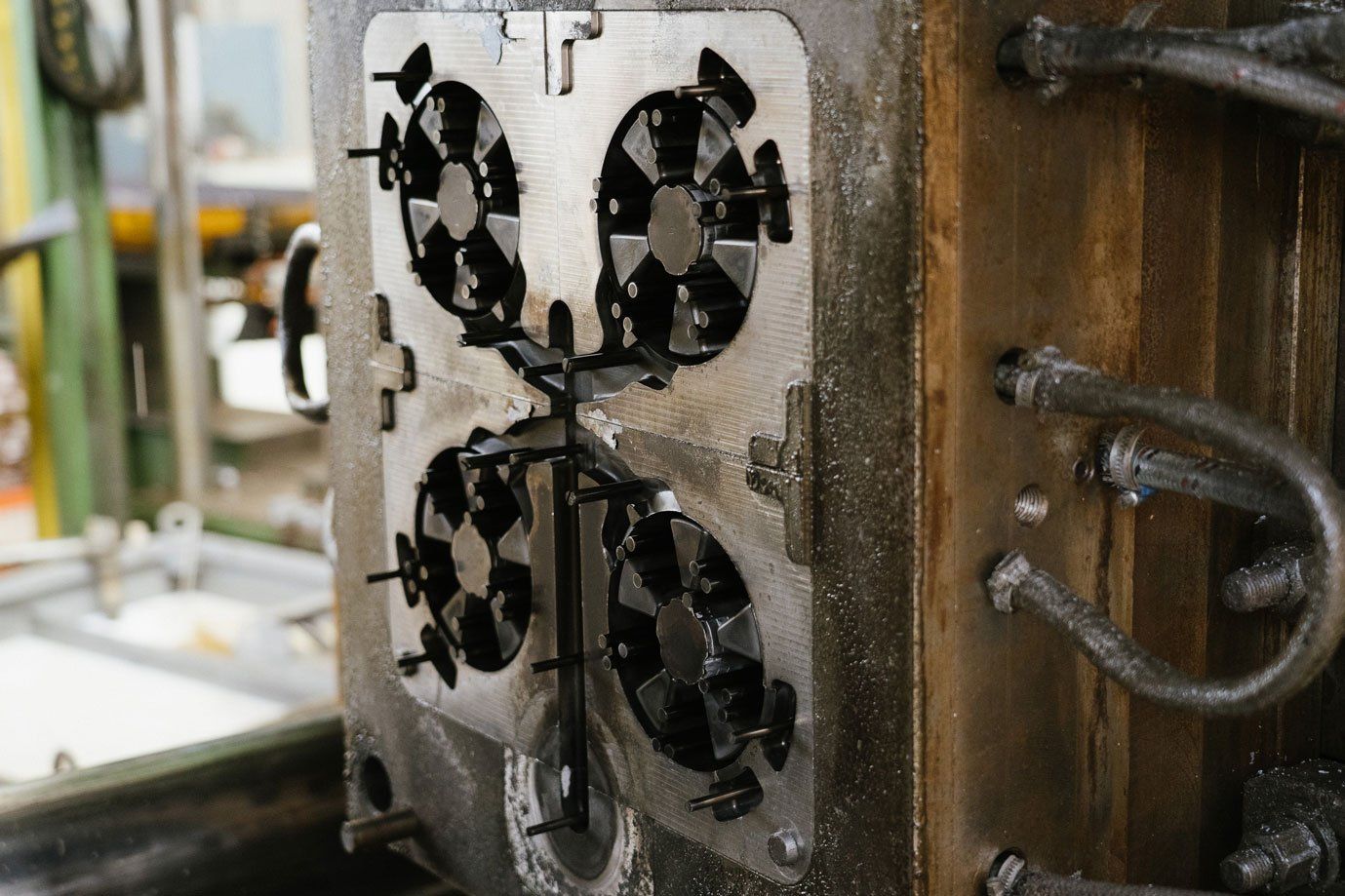

Aluminum alloy die casting

In recent years, aluminium is regaining its true value in society.

Highly malleable, low melting temperature, high recycling rate, these are the characteristics that make aluminium competitive and irreplaceable.

Its important presence in our products and the central role of aluminium alloy in a growing market, have pushed our company to set up an in-house department dedicated to aluminium alloy die casting.

At the end of each production step, the die-cast parts are subjected to a visual check, so as to complete the orders with the appropriate production times.

Once the production process is complete, all our products are subjected to a quality check that allows us to examine thoroughly the product using inspection machines.

To date, our die casting department operates in different sectors of aluminium alloy moulding:

- Moulding screws and covers for electric motors

- Die-cast rotors electric motors

- Screws moulding for die-cast aluminium extractor fans

- Wheels moulding for die-cast aluminium trolleys

- Die-cast aluminium joints moulding

- Die-cast aluminium door handles moulding

- Die-cast aluminium pulleys for hydraulic pumps moulding

- Die-cast aluminium motor reduction gearbox molding

- Die-cast aluminium supports moulding

Machines, technologies and workshop

Our die-casting islands are fully automated and comply with European safety and environmental standards.

The working capacity is about 200 tons of aluminum per month. We can mould up to 5 kg of die-cast aluminium products, with different alloys according to the customer's needs.

Our production centre consists of 3 fully automated die-casting islands with a capacity from 320 to 750 tons, finishing obtained by sandblasting, machining centre and workshop.

Finishing processes

At the end of the production process we offer finishing, turning and milling processes, which guarantee that the final product is glossy and worthy:

- Sandblasting, tumbling of aluminium alloy details

- CNC milling

- CNC turning

- Threading

- Deburring

Additional operative sectors at Ema Italy

The aluminium alloy die casting department is engaged in multiple moulding operations. At the laboratory in Osimo the following are moulded in die-cast aluminium:

- covers for electric motors and screws;

- joints and handles;

- wheels for trolleys;

- screws for extractors;

- pulleys for hydraulic pumps;

- supports and motor reduction gearboxes.